Thermal paper can be printed on both sides, which can reduce paper usage by up to 50%. This feature was introduced by NCR Corporation and helps lower operational costs related to storage, shipping, and waste disposal while also providing environmental benefits.

When studying the history of thermal paper, researchers note that scientists discovered the perfect combination of leuco dyes, and developers could create paper that changes color when exposed to heat. This chemical breakthrough eliminated the need for traditional ink cartridges.

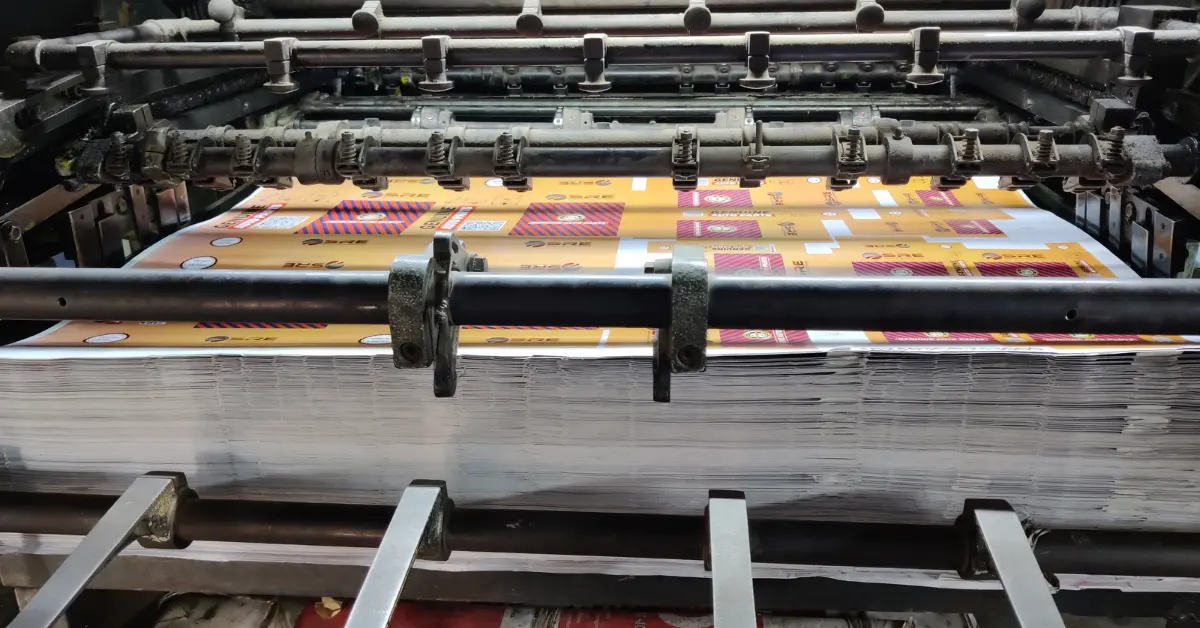

This history shows that Thermal Printing has become popular since the mid-19th century because of the unmatchable and interesting qualities associated with thermal paper. As it does not require ink or toner for printing, refills and receipt replacements can be avoided at high-volume printing places.

Thermal paper is a unique heat-sensitive paper in terms of cost-effectiveness, speed, reliability, durability, and efficiency because thermal paper receipts can resist smudging and also can avoid fading away over a short period of time.

Revolutionary History of Thermal Paper

The revolutionary history of thermal paper began in the 1960s when the 1st heat-sensitive paper was introduced. This paper revolutionized the printing industry by eliminating the use of ink ribbons or cartridges. Following is a brief timeline of how the thermal paper roll industry developed.

Role of National Cash Register (NCR) Corporation - 1960s

In the 1960s, the NCR Corporation primarily developed the first practical version of thermal paper for cash registers and point-of-sale (POS) systems. This version has a special coating that darkens on exposure to heat.

The NCR Corporation plays a significant role by introducing and licensing two-sided thermal printing technology. This technology allows printing on both sides, reducing paper usage by up to 50%.

This reduction lowers the operational costs of storage, shipping, and waste disposal and offers different benefits along with different environmental benefits such as sustainability and preservation of natural ecosystems.

Role of Japanese Inventions - 1970s

A crucial milestone in the history of thermal paper occurred in the 1970s, with the Japanese intervention in the thermal printing industry printing barcodes started gaining popularity in such office environments where cost-effectiveness along with the reliability of work was the first priority. So, thermal paper was started to be used in fax machines.

Japan’s entry into the barcode industry through thermal printing marked a pivotal role in the global supply chain, retail, and logistics sectors. Japanese companies pioneered the use of thermal printing technology for barcode generation, which replaced older methods like dot matrix and impact printing with faster, more reliable solutions.

Arrival of Automated Teller Machines (ATMs) - 1980s

In the 1980s, with the arrival of Automated Teller Machines, thermal paper was highly used for receipt printing purposes because of its durability and compact size.

Also, in the 1980s, Japan’s SATO Corporation became a global leader by introducing thermal transfer printing for barcodes. Thermal transfer printing offered high resolution and durability, ideal for product labels, warehousing, and logistics where barcodes had to withstand harsh conditions like abrasion and heat.

Toshiba TEC and other Japanese companies improved Direct Thermal Printing for barcodes, especially in applications requiring short-term usage, such as shipping labels and supermarket receipts.

Japanese companies like Brother, Seiko Epson, and Citizen Systems focused on compact, portable printers suitable for smaller workspaces or mobile applications. Their innovations allowed businesses to generate barcode labels on-demand in the field, thus improving workflows for sectors like healthcare and mobile retail.

Role of Modern Technology - 1990s - 2010s

In the early 1990s, several significant advancements transformed the thermal printing industry. These changes were driven by technological progress, evolving market needs, and growing demand for faster, more efficient printing solutions.

For example, businesses began moving from impact printers to thermal printers, which offered quieter, faster, and higher-quality printing. Moreover, people started to eliminate the need for ink or ribbons by using heat-sensitive paper, making it ideal for short-term applications like receipts or shipping labels.

Final Words

The History of Thermal Paper reveals how this technology has significantly impacted industries worldwide, transforming the way businesses handle transactions, logistics, and record-keeping.

Over time, advancements in coating techniques, chemical formulations, and environmental awareness have improved thermal paper’s durability, print quality, and safety, making it suitable for a variety of high-demand applications.